News

新闻中心

联系我们

移动电话:13620045661、13602381201刘工

电话:0769-85309665 传真:85322966QQ:1048038402、1559436599

电邮:bbk100@126.com

地址:广东省东莞市长安镇沙头358省道998号港芝科技园

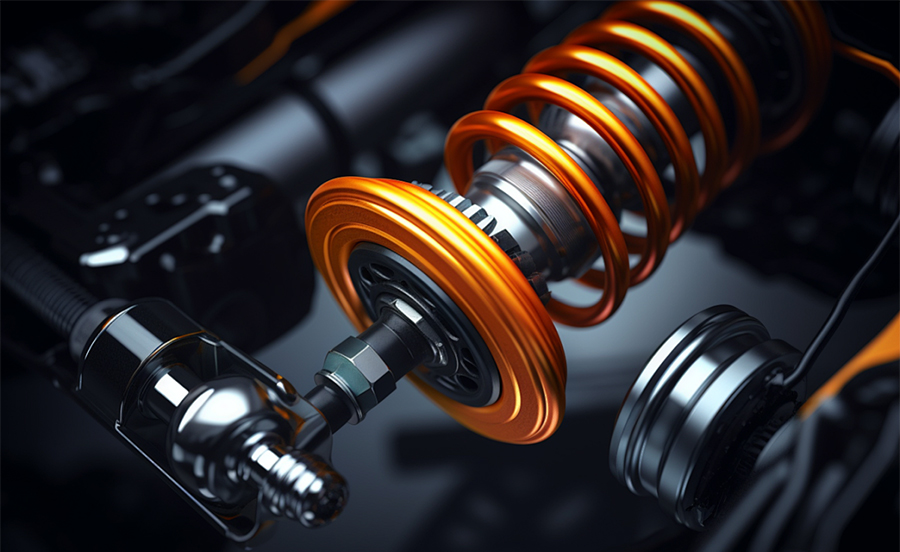

KALLER/DADCO compatible automotive mold nitrogen gas springs - BBK-JINGBA free pressure regulation + 30-50% cost-performance advantage

发布日期:2026-01-23

The automotive mold industry is moving towards precision and efficiency. The wide application of high-strength steel (HTSS) has raised higher requirements for elastic components - not only do they need stable elastic force, but also need to fit into the compact space of the molds. BBK-JINGBA (established in 2008) as an established brand of nitrogen gas springs for molds, has launched automotive mold nitrogen gas springs that are fully compatible with Swedish KALLER and American DADCO. These springs not only comply with ISO 11901 standards, but also support non-standard customization, and offer free pressure adjustment services. They solve the rebound problems of stamping parts such as automotive beams and frames. The price is 30-50% lower than imported products, and has helped enterprises like Guangdong Midea's white goods and Zhongshan wheel quantified production achieve stable production of 100,000 to 200,000 pieces.

The three core pain points of choosing nitrogen gas springs for automotive molds

1. Instability of spring pressure leads to product rebound: Traditional springs cannot meet the requirements for forming high-strength steel, while BBK-JINGBA nitrogen springs have constant spring pressure and a depressurization rate of ≤ 5%;

2. Imported brands have high prices and slow after-sales service: The procurement cost of KALLER/DADCO products is high, and the after-sales response requires more than 72 hours. Our side can provide a complete solution within 1 hour;

3. Limited mold space + mismatch of parameters: Support for non-standard customization (travel range 7-300mm, spring pressure 300N-200kN), and it is completely interchangeable with the dimensions of imported brands, without the need to modify the mold.

The 4 core advantages of BBK-JINGBA's nitrogen spring for automotive molds

【Import Compatibility】: Fully interchangeable with the KALLER X XG TU K CU CTX series and the DADCO U UX 90.10 C.090 C.045 series. Direct replacement is possible without the need for mold adjustment;

【Free Pressure Adjustment】: If the customer is unsure about the pressure level, they can receive on-site or mail-based pressure adjustment services until it is suitable for production needs;

【Rapid After-sales Service】: 1-hour response time, 24-hour on-site repair service to address mold downtime losses (brand core advantage);

【High Cost-effectiveness】: At the same quality level, the price is 30-50% lower than that of imports. 1 million cycle usage + 2-year free warranty.

Application Case of Nitrogen Springs in Automotive Mold Design

In the 5.73-meter automotive longitudinal beam bending process at Guangdong ** Auto Pressing Parts Factory, due to the traditional spring rebound issue, the product qualification rate was only 85%. After replacing the nitrogen spring compatible with KALLER from BBK-JINGBA, through free pressure adjustment services, the spring pressure was precisely matched to 4700N, resulting in a product qualification rate of 99.8%, a reduction of 60% in mold maintenance times, and an annual cost savings of over 150,000 yuan.

The automotive mold adaptation scenarios for BBK-JINGBA nitrogen gas springs

- Automobile longitudinal beam and frame stamping dies;

- Door and engine hood stretch forming dies;

- High-strength steel stamping forming dies;

- Multi-station progressive die clamping/unclamping devices.

If you are looking for cost-effective alternatives to imported brands such as KALLER and DADCO, or if you need custom nitrogen springs specifically for automotive molds, you can visit our official websites: www.bbk100.com, bbkspring.com, bbkdevelop.com for inquiries. BBK-JINGBA offers free pressure testing and 1-on-1 technical selection services, making mold production more efficient and cost control easier.